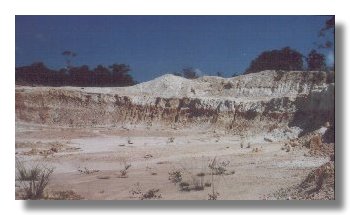

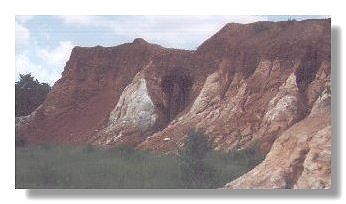

The raw materials are essentially low grade terra cotta clays, brought in from a distance of 80 kms for processing at the factory. The clays are varied and badly sorted, with much free quartz and associated minerals scattered amongst the deposits. Access to the site was badly organised, with flooding encountered during the rainy season, and no plan was in effect to identify the better areas of clay that would in turn result in a more stable body mix.

Test trenches and hand auger samples were carried out across the site, and a long term strategy developed to ensure basic standardisation of the material destined for use at the factory. Some landscaping was effected in order to remove the overburden, trees and bushes were planted around the perimeter to minimise the erosion of the clay seams.